The manufacturing business is one of the fields that is still developing in this age of technological disruption. The technological adaptation carried out to facilitate the factory production process is one of the markers of this industry’s growing development. One example is the use of a Factory Automation System.

What Exactly is a Factory Automation System?

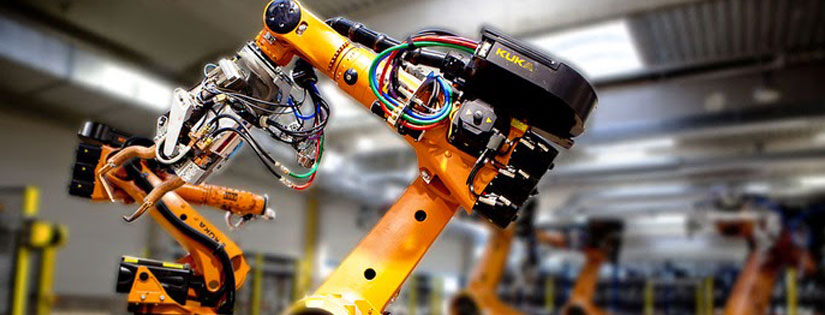

Factory Automation System is the application of a robot-based system. Its goal is to help manufacturers increase production while lowering production costs per unit. Factory automation, on the other hand, can solve a variety of additional issues, including protecting factory workers from being injured while operating production machines, overcoming human faults in machine operations, and enhancing production quality.

Types of Factory Automation System

Automatable automation

This sort of automation allows you to adjust the machine’s operation and setting using an electronic device. During batch production processes, automation systems will demand time and effort to reprogram machines. A crew mounting machine is an example of automation that can be programmed by the system. This machine can conduct configurations based on demands and is handy for automatically placing bolts based on specific product kinds.

Automated fixes

Fixed automation systems will create machines or industrial equipment to perform established jobs while following fixed production processes. Conveyor machines and mass manufacturing systems are two examples of continuous flow operations.

Factory Automation System is adaptable

The computer will control the system and apply it to potentially volatile items such as CNC machines in flexible automation. The CNC machine is an example of a flexible automation system application in which the instruction code sent to the computer has unique attributes for each specific work activity. During the manufacturing process, the machine will execute the necessary and suitable orders or instructions via the instruction code.

The Advantages of Using Factory Automation System

Can reduce production duration

The use of industrial automation in the company will certainly speed up production time. Given that human power and machine power are very different when producing an item, human power requires rest time while machine power is able to work without a break.

Reduce errors

By using manufacturing software, companies can reduce errors during production. This is because the production error rate by machines is lower than the human error rate. In addition, manufacturing information systems can measure the error rate during the production process.

Reduce employee burden

In using industrial automation in operational activities, companies can reduce the costs incurred to pay employee salaries. Reducing the number of employees can reduce the risk of security problems in work related benefits when you fall sick.

Increase production quantity

An increase in the amount of production also results in an increase in company profits. Automatically, the use of a manufacturing system results in the company’s ability to produce a product more quickly and productively.

Conclusion

In a nutshell, Factory Automation System is a technology that involves the use of mechanical, electronic, and computer-based information systems. This technology can assist businesses in operating and controlling production by assessing product efficiency, labour expenses, and production costs.